Chris Larsen, P.E. - Vice President of Engineering and Quality Assurance - ISS Leak Services

Aziz Darugar, P.E. - Director of Sales and Engineering - CADTech USA LLC

March 31, 2025

At Industrial Specialty Services (ISS), precision, safety, and efficiency are the foundation of their work. With over 400 dedicated technicians, 12 ISS locations, and more than 570 satisfied customers, ISS has established themselves as the premier provider of engineered technical solutions in the industry. With a mission to deliver the best solutions, ISS has taken the challenge to redefine its workflow to ensure safety, efficiency, and cost savings for its customers.

Among the most complex challenges ISS faces is leak sealing and repair—critical services that demand accuracy, speed, and custom-engineered solutions. By integrating the Artec Leo into their workflow and undergoing comprehensive training provided by CADTech USA, ISS has redefined the standards for precision scanning, machining, and repair, ensuring that their customers avoid costly shutdowns while maintaining the highest safety standards.

The Challenge: Leak Sealing with Absolute Accuracy

Leaks in industrial systems pose serious operational risks. Whether at a flange connection, elbow, straight run, "T" configuration, or another location, leaks must be addressed immediately with custom solutions tailored to the size, temperature, pressure, and chemical composition of the leaked substance.

Traditional measurement methods, such as hand measurements and conventional calipers, often lack the precision needed to capture the intricate geometry of piping systems. This lack of accuracy can lead to:

The Solution: Artec Leo, CADTech USA Training, and ISS’s Precision Machine Shop

To overcome these challenges, ISS implemented the Artec Leo, a state-of-the-art 3D scanner known for its portability, accuracy, and ease of use. To ensure seamless adoption and maximize the scanner’s potential, CADTech USA provided hands-on training to ISS technicians for 3D scanning, and to ISS engineers in processing scan data to perform Scan-to-CAD conversions effectively. By combining this cutting-edge technology with ISS’s in-house precision machine shop, they can now design and manufacture leak repair enclosures with unmatched speed and accuracy.

A Game-Changing Workflow with Artec Leo

Here’s how ISS, with the expertise of CADTech USA, leverages the Artec Leo to enhance their leak sealing and repair process:

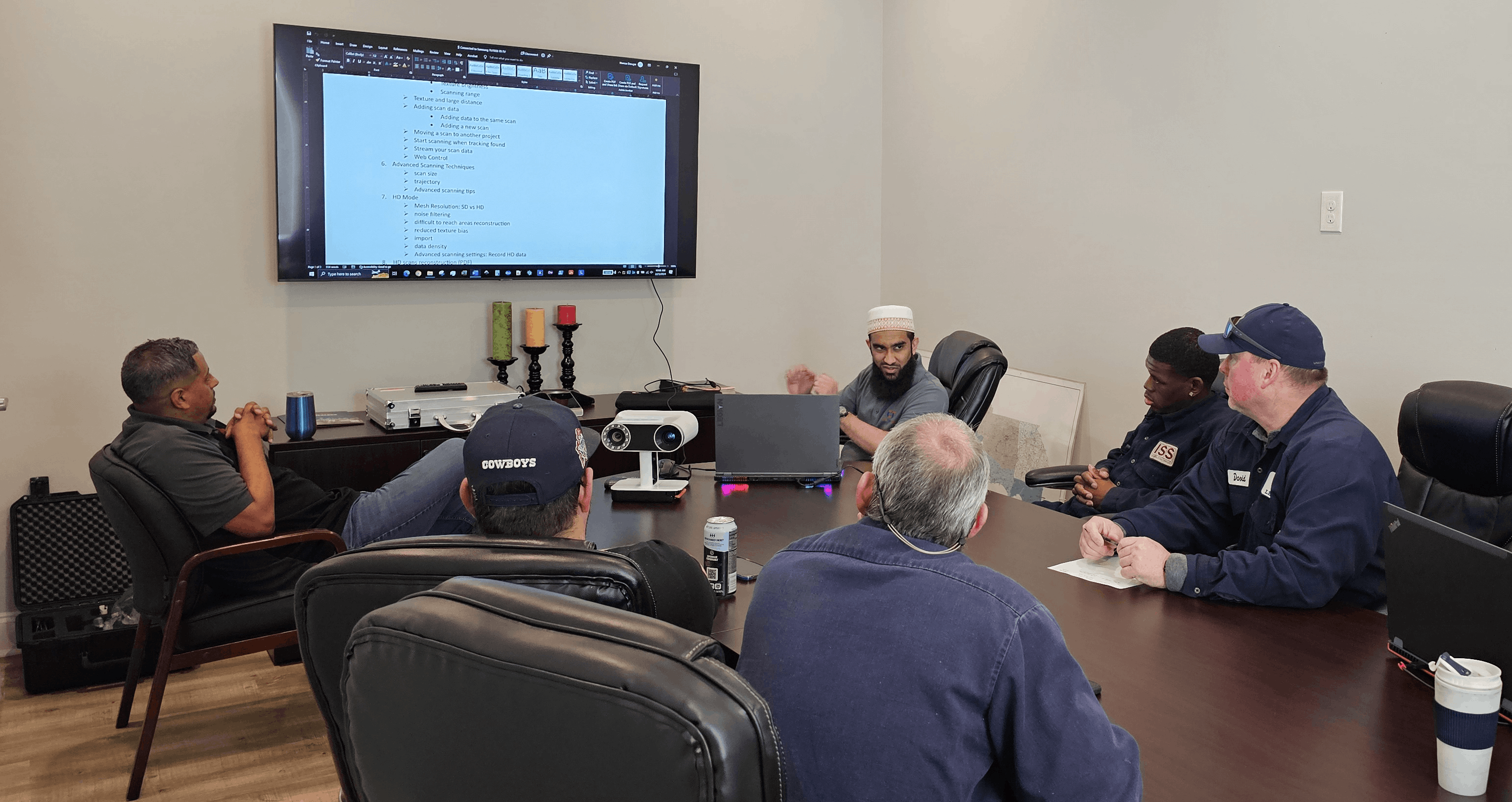

1. Comprehensive Training by CADTech USA

Training ISS personnel at their Louisiana facility

2. On-Site 3D Scanning

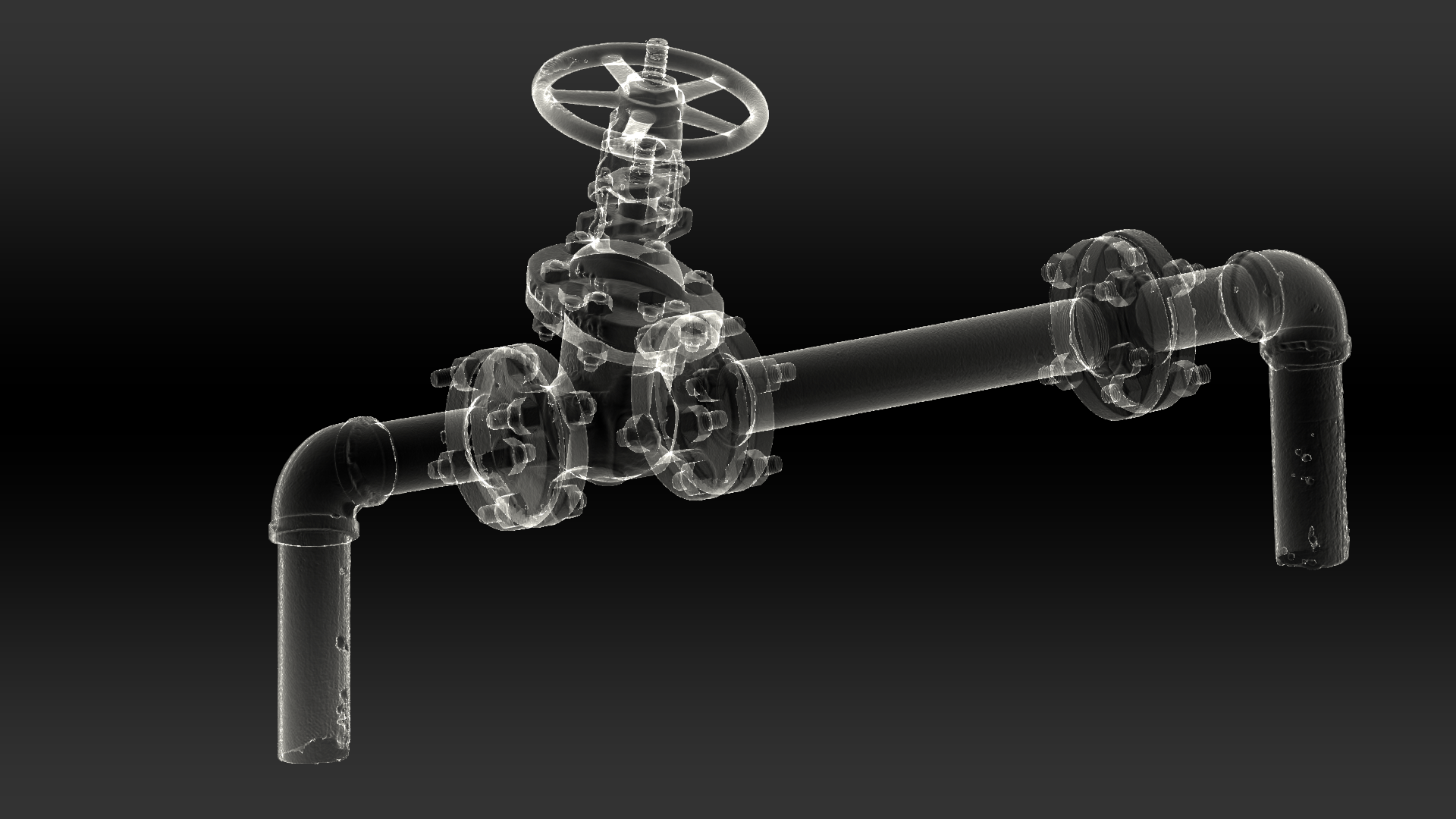

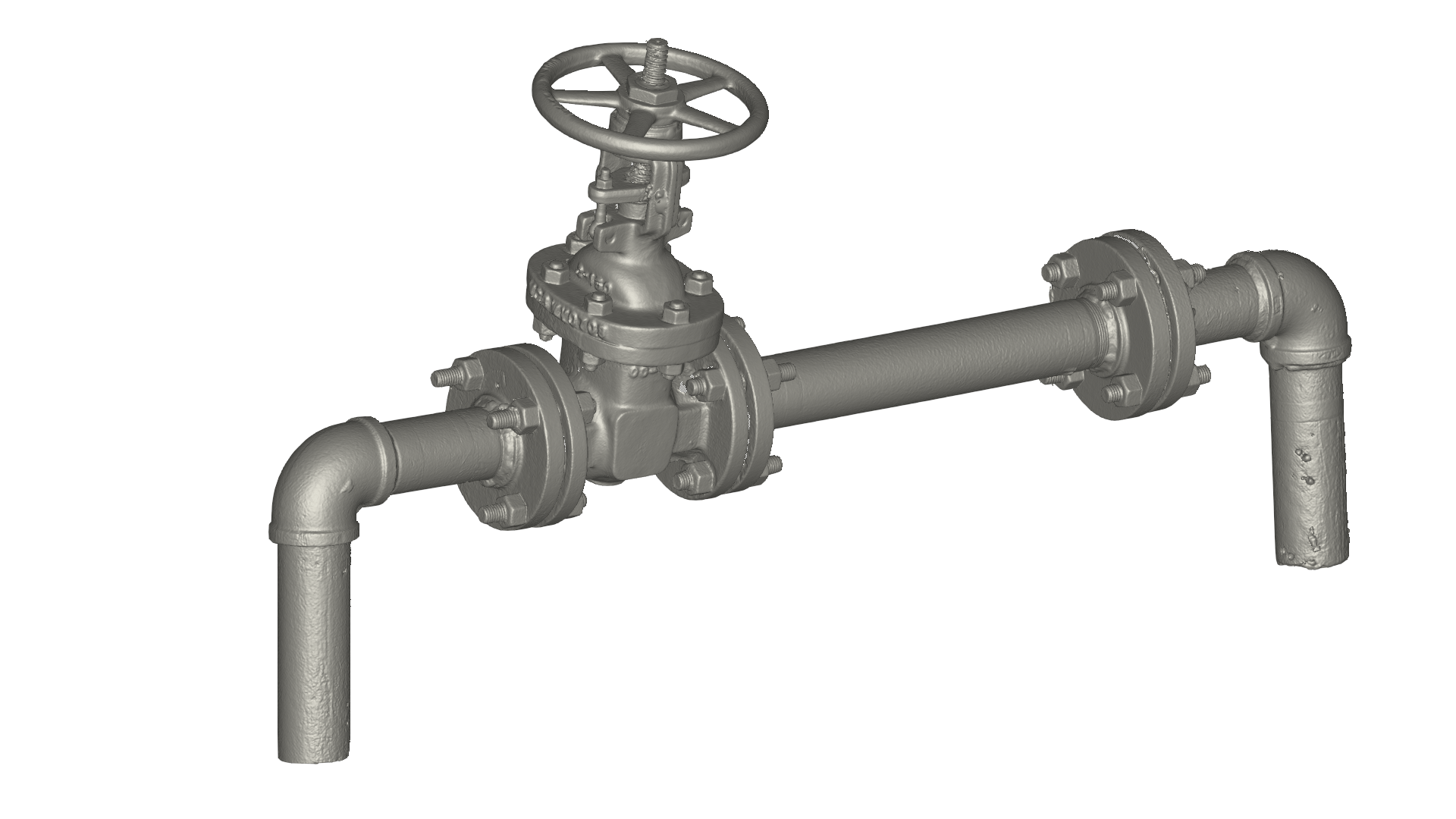

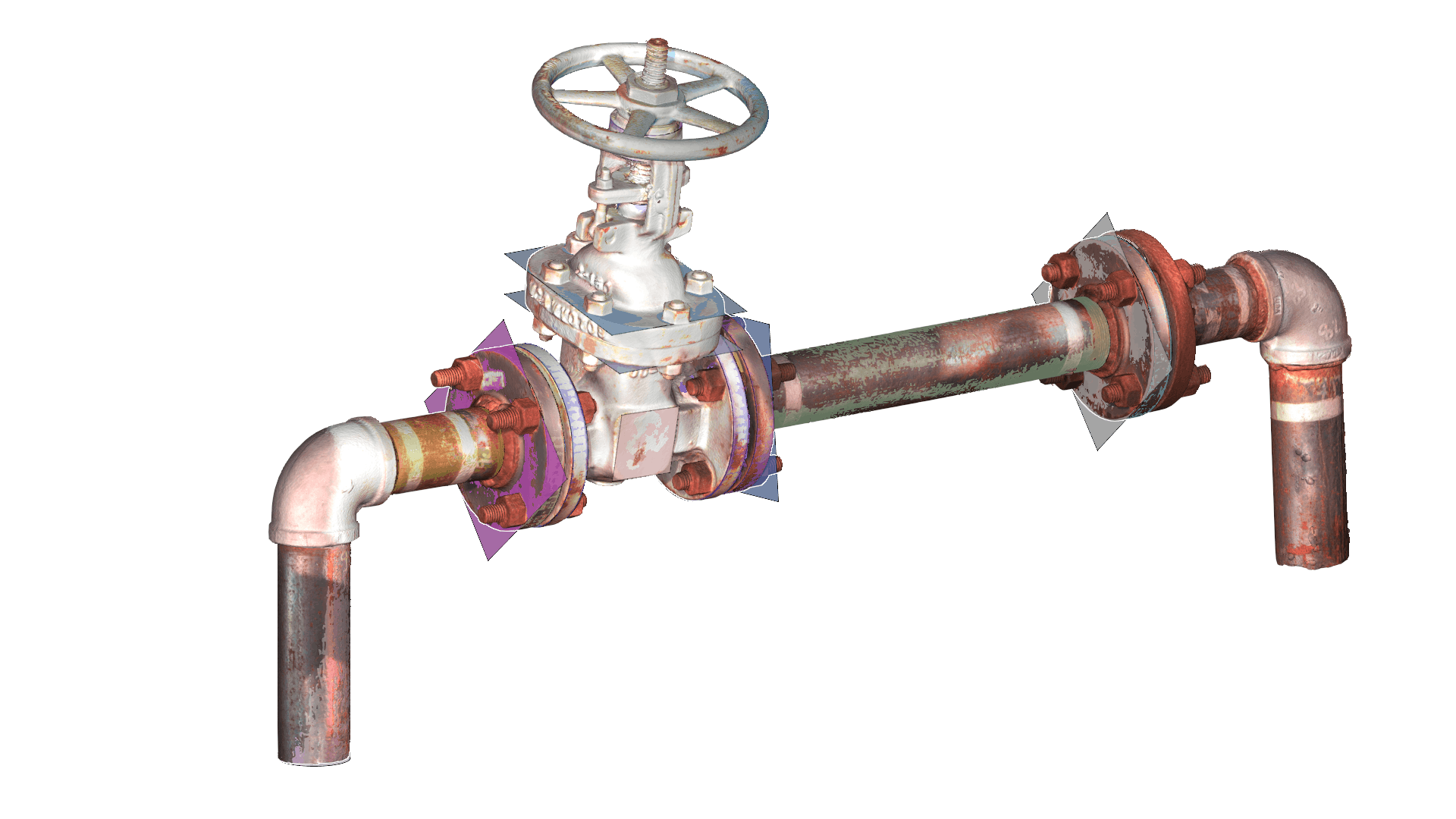

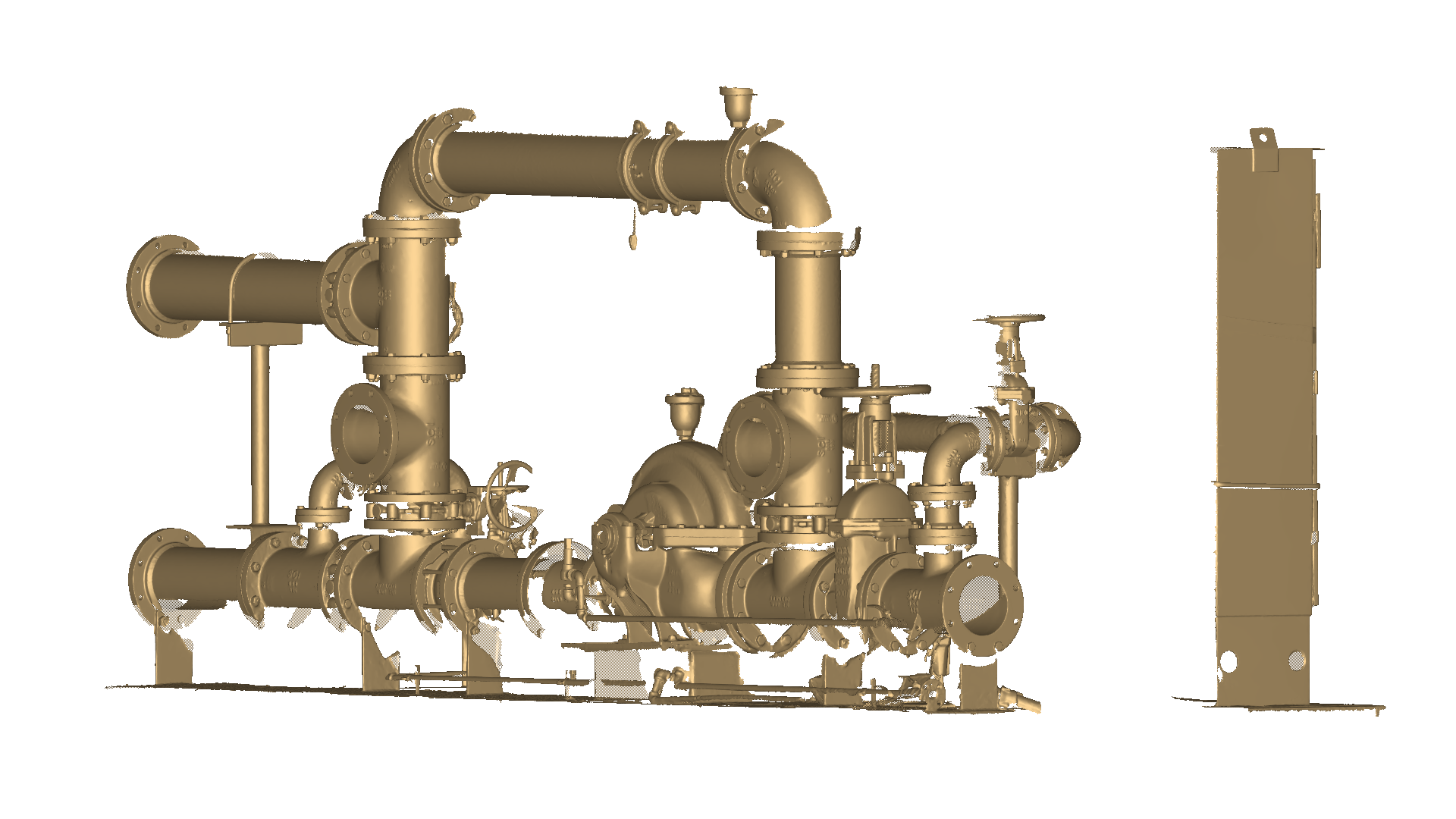

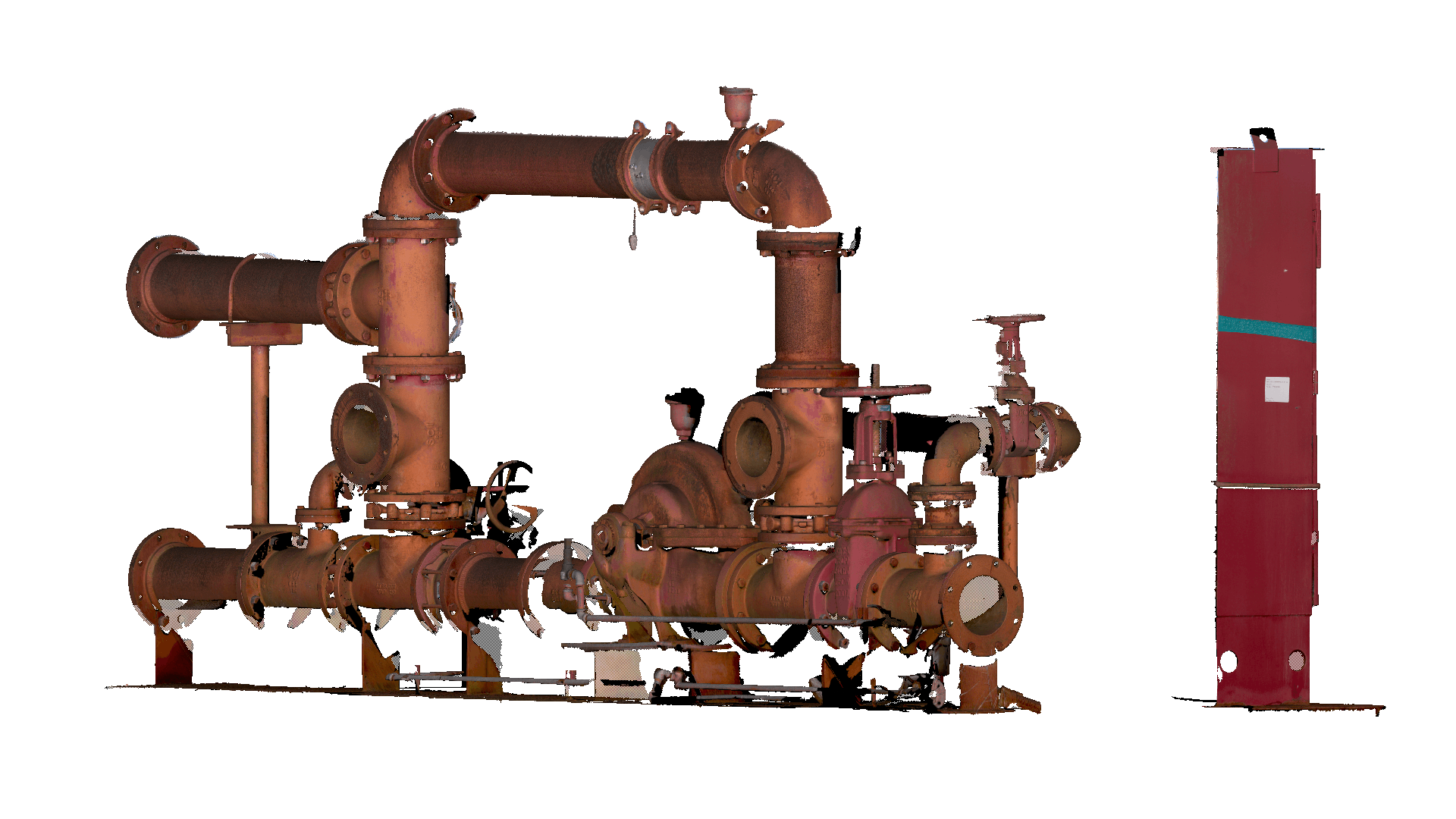

Scanned Model

Scanned Model Scanned Model

Scanned ModelScanned mesh from on-site 3D scanning with the Artec Leo

3. Post-Processing in Artec Studio

Constructs Only

Constructs Only

Mesh with

Mesh withConstructs added in Artec Studio to a mesh scanned with the Artec Leo

4. CAD Modeling and Custom Enclosure Design

5. Precision Machining at ISS’s In-House Machine Shop

6. Rapid Deployment and Installation

Unmatched Benefits with Artec Leo and CADTech USA Training

Precision and Accuracy:

The Artec Leo provides highly accurate measurements, capturing complex geometries that traditional tools cannot handle. With the expertise gained from training with CADTech USA, ISS technicians and engineers can fully utilize these capabilities.

Scanned Model

Scanned Model

Scanned Model

Scanned ModelISS technicians can scan complex spools with ease with the Artec Leo

Cost Savings:

Leaks can result in millions of dollars in lost revenue due to unplanned shutdowns. By providing fast, customized leak repair solutions, ISS helps customers avoid costly downtime and prevent safety hazards.

Efficiency:

What once required extensive manual measurement and adjustments can now be completed in a fraction of the time, allowing ISS to respond to emergencies faster than ever before.

New Opportunities:

With the Artec Leo and CADTech USA’s training, ISS will expand its capabilities to take on more complex leak sealing projects, including:

ISS and the Future of Leak Sealing

ISS’s adoption of the Artec Leo, supported by CADTech USA’s expert training, is not just about improving efficiency—it’s about setting a new industry standard for precision and safety. By integrating advanced 3D scanning technology with world-class engineering expertise, ISS ensures that they continue to lead the field in engineered leak repair solutions.

If you’re facing a critical leak and need a fast, precise, and reliable solution, contact ISS today. With their advanced 3D scanning and machining capabilities, powered by CADTech USA’s training, ISS can save you time, money, and unnecessary downtime.

Contact us if you have a project that requires 3D scanning complex pipe spools in off-site or remote locations.